|

Jin Luding Welding (Shandong) Co., Ltd

|

Automatic girth seam welding machine for electromagnetic flowmeter.

| Price: | 180000.0 RMB |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to Basket | Add to My Favorites |

| HiSupplier Escrow |

Product Detail

1\Suitable for welding pipe-to-pipe, pipe-to-elbow, pipe-to-3 Way pipe, and pipe-to-high neck flange butt-joint; pipe-to-flange and elbow-to-flang

Technical specifications:

Model | H3660-T |

Joint Type(s) | Pipe-to-pipe, pipe-to-high-neck flange butt-joint, |

Three-jaw self-centering chuck | Central hole diameter: Φ 360mm; (Optional: Three-jaw self-centering electric chuck) |

Positioner | Positioning motion range: 0~90°;Rotation radius: 500mm |

Oscillator | Oscillation width: 0~40mm; Oscillation speed: 0~20mm/s; |

Arc voltage controller | Standard slide track range: 0~40.0mm; |

Automatic wire feeder | Suitable for wire diameter: Φ1.0mm |

TIG torch | LD400 water-cooled TIG torch; |

Control Terminal | Color touchscreen control terminal |

Storage capacity | Able to store 30 sets of welding procedures |

Power source | Panasonic YC-400TX TIG power source |

Manipulator arm travel distance (mm) | X×Y×Z : 800×900×30 x-axis effective travel distance : 300 |

Overall dimensions | 1300×1900×2000 (Excluding control cabinet) |

Input power/ voltage/ frequency | Panasonic power source:30KW/380V/50Hz, Control cabinet: 1.0KW/220V/50Hz |

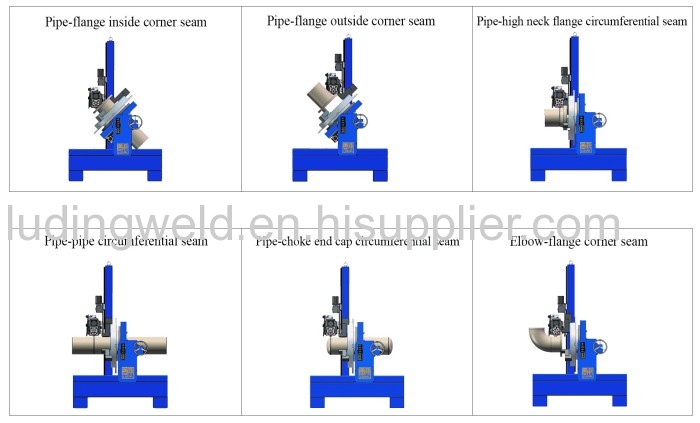

Applicable joint type:

Overall dimensions:

Dimensions | A Length | B Width | C Height | D Central hole | E Center height | F Rotation radius | G Control cabinet |

H3660-T | 1300 | 1900 | 2000 | 360 | 860 | 500 | 1000 |

Features of H3660-T Automatic Welding Machine:

1,Suitable for welding pipe-to-pipe, pipe-to-elbow, pipe-to-3 Way pipe, and pipe-to-high neck flange butt-joint; pipe-to-flange and elbow-to-flange corner joint.

2,Suitable for welding various materials such as carbon steel, low-alloy steel, stainless steel, and copper.

3,Equipped with TIG welder.

4,Integrated design with compact and reliable structure; three-jaw self-centering chuck offers precise rotation and positioning.

5,The machine comprises a comprehensive integration of a three-dimensional manipulator arm, a positioner, and a welding torch angle adjustment mechanism. This sophisticated combination ensures a seamless transition of various positions and angles for the torch, enabling precise and efficient welding operations.

6,The operating system of the machine features a user-friendly touchscreen interface, facilitating effortless programming.

7,With a storage capacity for 30 sets of welding procedures, the system enables direct retrieval of the corresponding welding procedures based on specific weldment specifications.

8,Equipped with arc voltage controller (AVC) and oscillator (OSC).

9,The automatic wire feeder is equipped with automatic wire retraction and impulse wire feeding functions, ensuring precise and accurate wire feeding.

10,A forced circulation water cooling unit is built into the machine, guaranteeing reliable and uninterrupted operation for extended periods.

11,The machine features a one-touch operation that automates the entire welding process. It also allows real-time intervention for adjusting welding parameters as needed.