|

Jin Luding Welding (Shandong) Co., Ltd

|

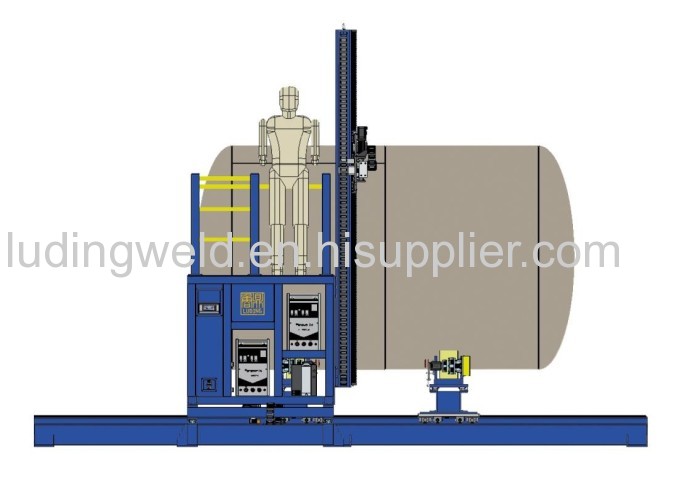

Automatic welding machine for girth seam and straight seam of large tanks

| Price: | 360000.0 RMB |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

During circumferential seam welding, the welding operation is performed using a welding manipulator arm in conjunction with a CNC roller frame to driv

Technical specifications:

Model | HZG3050-T |

Tank specifications (mm) | Diameter: Φ1000~Φ3000 Tank length ≤ 5000mm+2 times the tank end cap length. Tank wall thickness: 3-12mm |

Power source | Panasonic YC-400TX TIG power source |

Input power/ voltage/ frequency | Panasonic power source: 30KW/380V/50Hz Control cabinet: 1.0KW/220V/50Hz |

Overall size (mm) | See Overall dimensions for details |

Control Terminal | Color touchscreen control terminal |

Storage capacity | Able to store 40 sets of welding procedures. (30 circumferential seam procedures + 10 longitudinal seam procedures) |

Oscillator | Oscillation width: 0~40mm; Oscillation speed: 0~20mm/s; |

Arc voltage controller | Standard slide track range: 0~40.0mm; |

Automatic wire feeder | Suitable for wire diameter Φ1.0mm |

Video surveillance | Optional |

Applicable joint type:

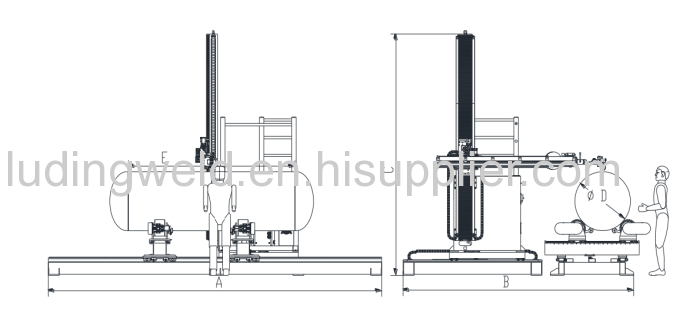

Overall dimensions:

Dimension | A Length | B Width | C Height | D Tank Diameter | E Longitudinal seam length |

HZG3050-T | 8000 | 4000 | 4000 | 1000~3000 | Not greater than 5000mm+2 times the tank end cap length. |

Features of HZG3050-T Automatic Tank Welding Machine:

1,During circumferential seam welding, the welding operation is performed using a welding manipulator arm in conjunction with a CNC roller frame to drive the rotation of the weldment. For longitudinal seam welding, a welding method is employed where the weldment is translated or moved while welding takes place.

2,Simultaneously adaptable for welding the circumferential seam between the tank body and tank end caps, the welds between flanges and the external corners seam of the tank body, as well as the longitudinal seam welding of the tank body.

3,Suitable for welding various materials such as carbon steel, low-alloy steel, stainless steel.

4,Equipped with TIG welder.

5,Split design with compact and reliable structure

6,The welding process utilizes a roller frame as a supporting and driving mechanism. The roller frame is equipped with four sets of rollers, with adjustable spacing between them. Each set of rollers is powered, resulting in efficient weldment loading and smooth transmission during the welding operation.

7,Machine comprises a comprehensive integration of a three-dimensional manipulator arm, a welding torch angle adjustment mechanism. This sophisticated combination ensures a seamless transition of various positions and angles for the torch, enabling precise and efficient welding operations.

8,The operating system of the machine features a user-friendly touchscreen interface, facilitating effortless programming.

9,With a storage capacity for 40 sets of welding procedures, the system enables direct retrieval of the corresponding welding procedures based on specific weldment specifications.

10,Equipped with arc voltage controller (AVC) and oscillator (OSC).

11,The automatic wire feeder is equipped with automatic wire retraction and impulse wire feeding functions, ensuring precise and accurate wire feeding.

12,A forced circulation water cooling unit is built into the machine, guaranteeing reliable and uninterrupted operation for extended periods.